Want to make big power without the expense of buying longer rods, or a deck-plate block? This is the answer. After 5 years and over 250k in development these blocks got a bad name due to a Youtube knucklehead assembling an engine and not seating in his wrist pin clips and the block failing at 900hp. Since then, they have been involved in some of the biggest builds in the diesel community making almost 4,000hp at the crankshaft. They work and are very sought after, and we are not producing any more. A unique opportunity to get the last of the line. Designed after a full year of research and FEA studies.

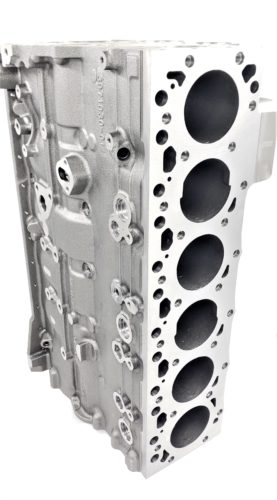

This block features a

-1″ thicker deck-

-OEM 6.7 deck height

-1″ thicker cylinder base

– the cylinder wall is 2″ shorter due to the extra material at top and bottom of the cylinder

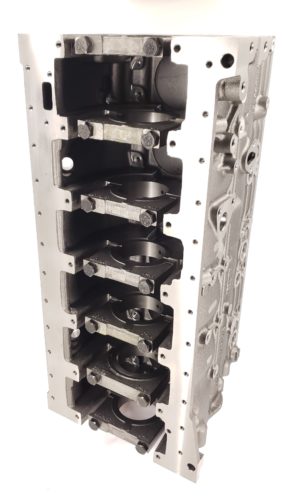

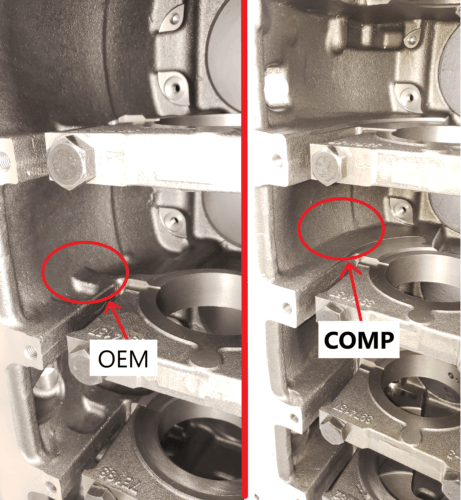

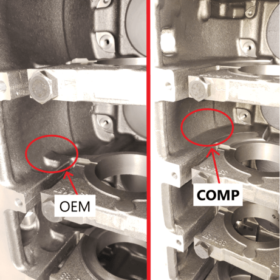

-Much Thicker main webbing

– improved 300 MPA high tensile alloy

-High tensile alloys should be honed with diamond hone.

-Cam oiling from mains has been shrunk from 7mm to 5mm for improved bottom end strength

-Do not tap main holes deeper, this is the source of the failure for most of the block failures we see

-Due to the many requests we have for different bore sizes we left the bore as cast so it can be anything you want, from approximately 4.0″ to 4.250″

-The thinner the wall, the less cylinder pressure you can run without failure 😉

-These blocks need to be bored and honed to final size.

-be sure to bore .450″ lower than the bottom of the cylinder for piston skirt clearance.

-the crankshaft may need to be clearanced

-Our race crank usually drops in without additional machining